Ok, it’s a bit of random post, quite unrelated to my usual topics. Italy slowly is starting to ease the lock-down, but for a couple of months I have mostly been living indoors, and in my room more than usual.

Lock-downs have their plus sides. I decided to make use of an old exercise bike (a Diadora Genesis DB7). It had been lying around in our house, unused and unloved, so I decided to adopt it and give it a new lease of life. Even though I have taken to running in the last year and a half, I still enjoy a good sweat-out on the exercise bike, while I can comfortably watch a documentary. It also gives my legs a break from the pounding they get as I hit the pavement, while still getting some cardio.

The bike had surely known better days. Electronics and (magnetic) resistance were working fine, but within very few weeks of re-use, the old transmission belt finally gave up its ghost. It must have been long overdue: when I removed the outer shields, I literally collected the remains of the belt reduced to a black powder. Enough of the belt survived (part of it was reinforced with a steel cable) for me to manage to measure its length, 990 mm.

The next step required some intuition, and investigation. I could find no technical literature regarding the transmission belt for this particular model of bike. I guess most clients are likely to replace their bike after many years rather than fix it, and — let’s face it — it’s not exactly in the company’s interest that you fix it than buy a new one! Of course, if I had to pay for the service, it might have well been cheaper to replace. But I love the challenge of fixing something — very much my dad’s son in this!

I presumed (correctly) that industry standard belts were in use. After all, tt makes commercial sense even for the manufacturers. I could easily see the grooves on both the larger black wheel driven by the pedals, as well as a smaller one at the side of the magnetic resistance wheel.

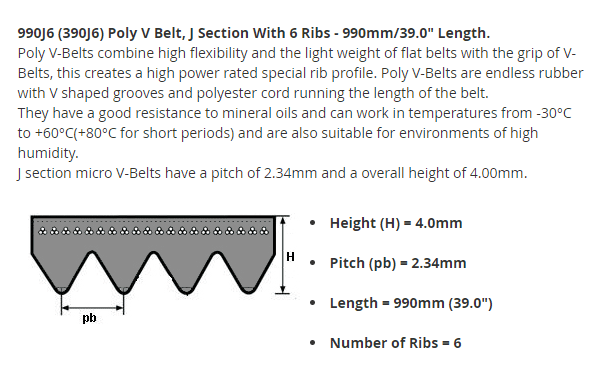

A few Google searches later, I was initiated into the world of Poly-V belts, and their various standards. These are your typical driving belts, used in anything from home appliances, cars, to heavier industrial machinery — with different standard types according to their application. A quick measurement of the distance between the grooves on the wheels suggested that I needed a J-type profile (2.34mm between ridges), and one with 6 ribs. I already knew it was 990mm long.

Unfortunately, I couldn’t find where to buy this particular belt in Italy, but I found online a shop in the UK — www.bearingsrus.co.uk [and no, I’m not getting paid for this!]. They had all the imaginable belts I could have wanted, so I quite easily found the type I needed — Poly-V belt, J section with 6 ribs, 990mm. I ended up spending more on the post than on the belt, since the company uses signed-for mail when delivering to Europe (Carriage expenses are far cheaper to the UK). But I figured that for something like €20 total, it still made sense.

Almost two weeks later — well, Covid-19 has slowed things down — the belt arrived. I only needed to dismantle the resistance wheel, and figure out the way to fit the belt correctly. A few minutes later — voilà! — the bike was functioning again.

After the first use, I noticed that I needed to adjust properly the idler bracket. Over the years it must have loosened just slightly, which meant that the transmission belt was touching the side of the resistance wheel (as in the photo). This may have been one of the causes, perhaps, for the old belt to wear out. A quick adjustment, and now the belt was properly in place, and the bicycle is working perfectly fine!

Now, I’m afraid I have no excuses to start exercising regularly again!

Like father like son 😅